Our Mission

At iEngineering Australia, our mission is to enhance efficiency, ensure quality control, and deliver

customer satisfaction through innovative engineering solutions. We are committed to global standards

and sustainable solutions that create long-term value for our clients and communities.

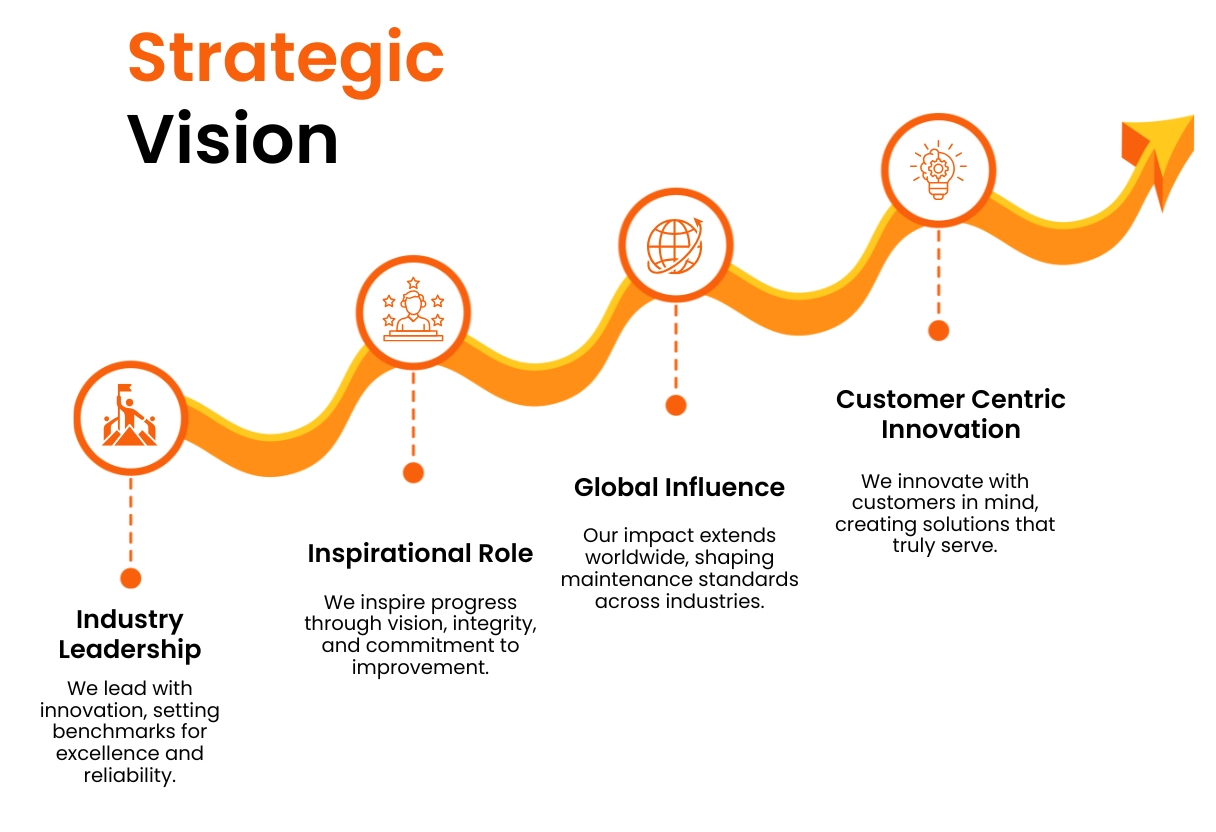

Our Vision

Our vision is to be a global leader in engineering solutions, driving industry leadership, innovation,

and customer-centric growth. We aim to inspire through global influence, foster expansion and growth,

and play an inspirational role in shaping the future of engineering.

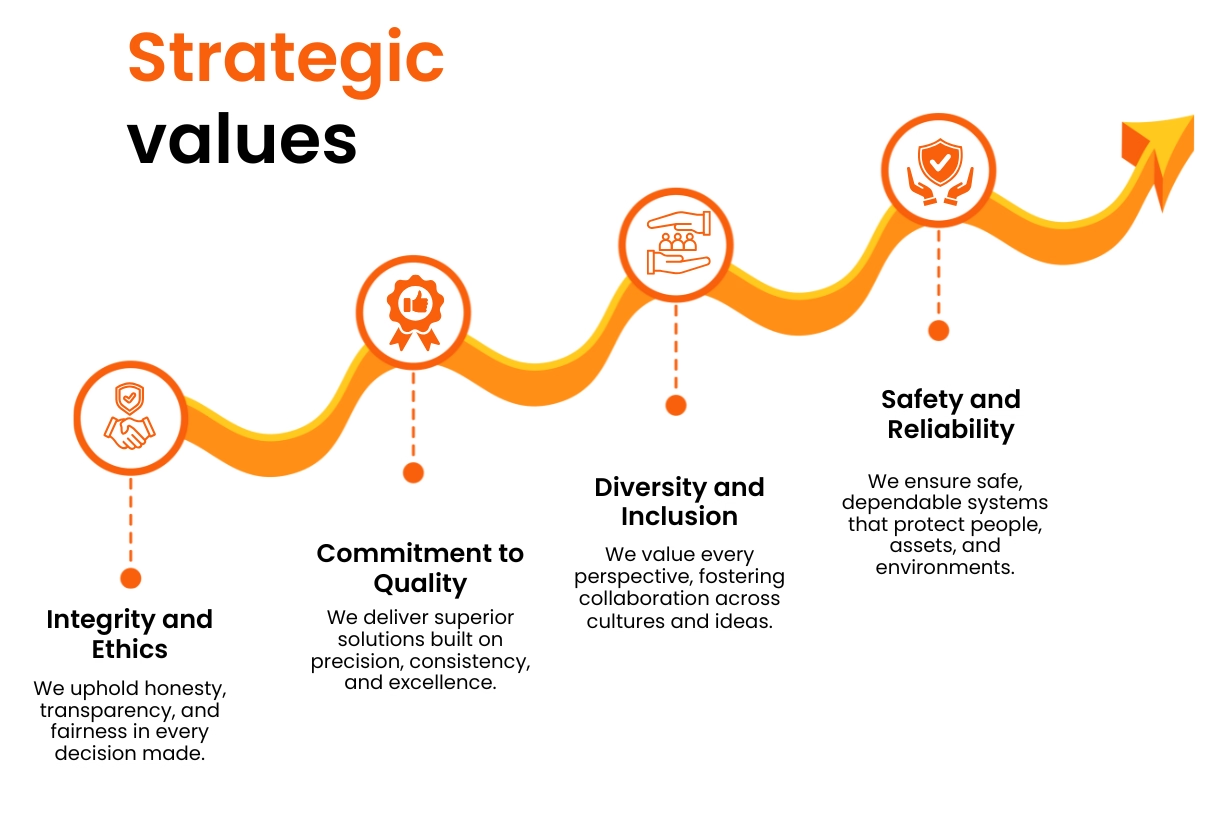

Our Values

Our values guide everything we do: integrity & ethics, a strong commitment to quality, and diversity & inclusion.

Safety, reliability, and continuous improvement are the cornerstones of our success, enabling us to deliver trusted

and innovative solutions worldwide.